PRELACTIA® is the cost-efficient barrier preform for liquid dairy products (LDP) in PET bottles. PRELACTIA® stands for innovative bottle designs and a revolutionary shelf life of up to 6 months.

The PRELACTIA® preform consists of a double-layer design: a gray interior wall that is impervious to light and a white outer skin. Both layers are precisely defined and consist of PET. As a result, PRELACTIA® bottles are optimally suited for recycling.

PRELACTIA® is exclusively available with premium machine technology from Netstal. The PET-LINE 2C production system offers maximum flexibility and, if needed, it can also be used for standard preforms (CSD, water).

Custom and ergonomic bottle shapes with which the products stand out at the point of sale

Pure white and particularly light bottles that strengthen your product position-ing

Absolutely tight and resealable

The best light barrier for a revolutionary shelf life of up to 6 months

A bottle made from pure PET that is particularly easy to recycle

Highly cost-efficient packaging for milk drinks and milkshakes

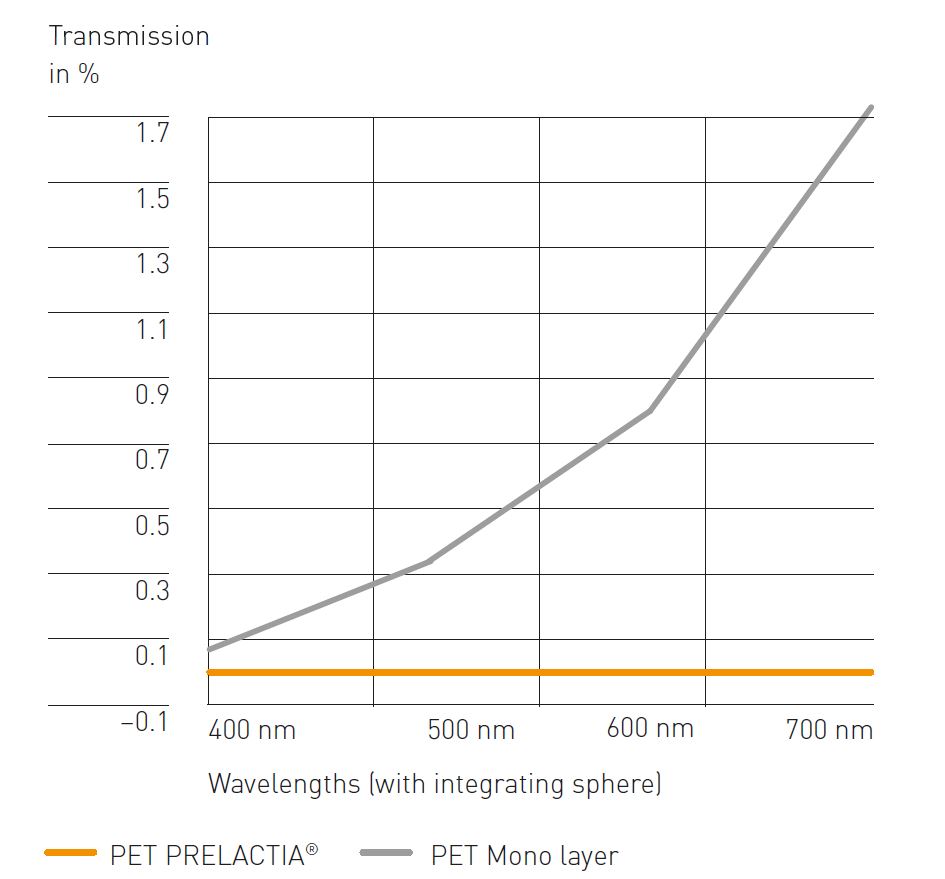

The double-layer design guarantees a highly effective light barrier. Nearly 100% of the visible light (400 nm to 700 nm) is reliably blocked. The result is a shelf life of up to 6 months.

• Up to 70% less titanium oxide added

• About 30% lower market price for PET granulate

• About 20% lower weight

• No loss of material during injection molding and blow molding

• Absolutely tight bottle without additional aluminum seal